What Makes The Best Aftermarket Quadco Teeth For Sale

Are you looking for the best aftermarket Quadco Teeth for sale? It is necessary to understand that the performance of your mulcher will depend on the nature of parts that you acquire. Among the most important parts are the teeth. It is therefore important to ensure that you go for the best aftermarket teeth for sale.

Quadco teeth are considered ideal for your operations, especially if you are looking for an on-budget order. You will realize that the said teeth are generally cheap as compared to others. It is, however, important to ensure that you are amply informed on what makes the best Quadco teeth for sale. Here are some of the things you should be on the lookout for:

Quality

The quality of the Quadco teeth you have chosen is what matters the most. A majority of operational activities in a Mulcher are reliant on the degree of quality. It is therefore important to consider the quality of the teeth you are about to buy. The good thing about Aftermarket Quadco teeth is that they are designed in the best way for the sake of upholding quality operations.

Manufacturer

The first question you should ask yourself is where you can get the Quadco teeth for sale and who the manufacturer is. The good thing is that Quadco is known as a good brand of mulching parts hence you cannot go wrong with the choice. It is, however, important to ensure that the dealer you have chosen only processes quality parts and nothing less.

Durability

It would be the best experience to get Quadco teeth for sale that will offer a long service before replacement is rendered necessary. The idea here is to operate within a cost-effective plan. This can be achieved by buying top quality Mulching teeth since they will serve you for a significantly long time without faults.

Compatibility

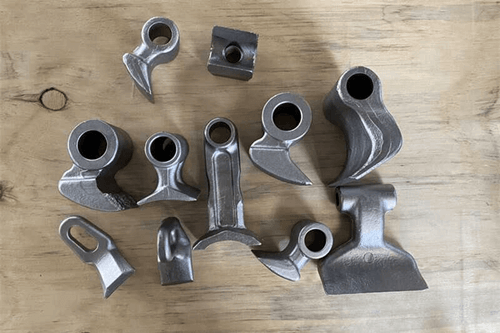

It is important to acknowledge that Quadco Teeth for Sale come in different sizes, types, and shapes. This, therefore, implies that your personal needs will be the guide on which teeth you should buy. Make sure that your choice serves all your needs fully.For more information on Quadco Teeth: visit site