Why Aluminum Forging Temperature Is A Major Factor

Well, this is a question that can be addressed in various ways. First, it is important to mention that there is a range of aluminum alloys in the market. These alloys have varying crystallization levels, and this is one of the factors that would make their forging temperatures vary.

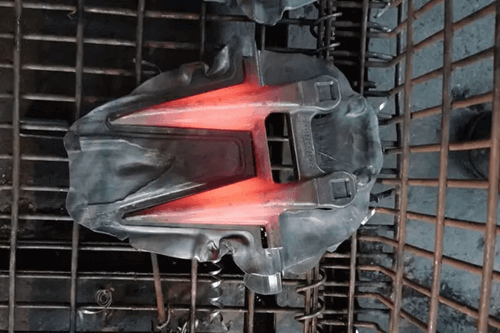

However, for pure aluminum, the forging temperature is slightly lower, with the recommended range being 300°C to 480°C. This temperature is just below the melting point of around 660.3°C. Depending on the punching power hot forging equipment, these temperatures can be varied.

Why Aluminum Forging Temperature Affects Quality

The aluminum forging temperature determines the quality of forgings in a number of ways. One of them is the state at which the metal has been hot forged. Important to note is that for the forgings to achieve maximum hardness and strength, the metal being forged must have achieved the crystallization temperature.

That’s why it is recommended that the right aluminum forging temperature is achieved so that the forgings can get maximum grains when forging. Note that the quality of the forgings is greatly determined by the hardness and strength of the forging.

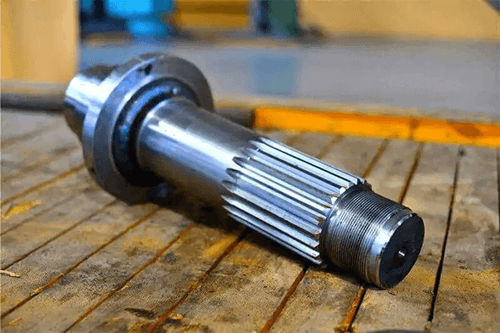

The aluminum forging temperature also determines the longevity of the forgings. This is because the hardness and strength of the forging greatly affect their resistance to the abrasive conditions.

The bottom line is that you must get the aluminum forging temperature right to produce the best quality forgings. If you are forging aluminum alloys, you need to ensure that you have gotten the temperature correct.

Visit https://www.hotforgingchina.com/, and you’ll be impressed by their collection of hot forged products.